Specialty HVAC

Outdoor Air Dampers:

Egis Corporation will measure old inefficient outdoor air dampers with our talented sheet metal team. We will provide manufacturers specifications on material, leakage, actuators and special install requirements. Egis Corporation will extract old dampers then install new.

Condensate Water Issues:

Air bypass around CHW coils will lead to increased supply temperatures and high air velocities. High air velocity can push condensate water all over the coil, pan and fan chambers in interior of the air handler.

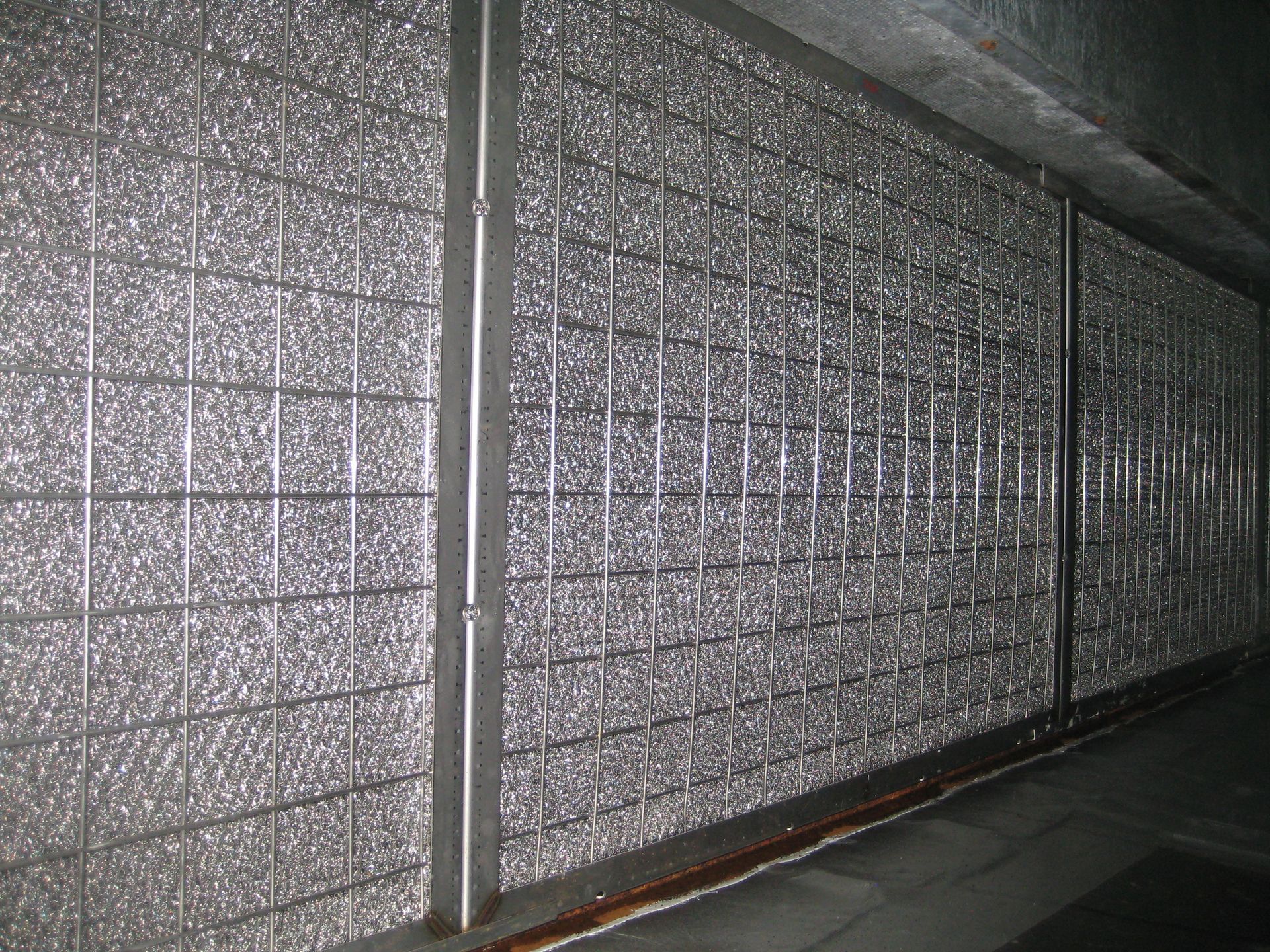

Air bypass at coil.

Air under coil and coming into fan chamber.

On Site videos of Air Bypass Issues

Condensate Water Solutions:

Egis Corporation will seal all bypass around coils with stainless sheet metal. We will use airflow meter to verify bypass seal is complete.

We will measure air velocity and pressure drops at coil. We will safely get inside equipment when approved. Condensate water trap and piping can be replaced with engineered "Costguard" Drain Seal. Drain seal on rooftop units will have drawings and sizing based on models. Larger air handling units drain sealing will be specially designed.

Air Leakage

- Air Handling Unit Equipment Access Doors- New, Gasket,Handles

- Air Handling Unit and MER duct Hardcast Taping

- Vibration Isolator replacement

- Metal replacement

HVAC Equipment Assessments:

Egis Project Management uses our Procore technology to inspect HVAC equipment. Our inspection POD breaks down common deficiencies found in equipment. The inspection POD is then embedded in the drawings of your equipment. We take pictures of the unit, then use Procore's photo tools to place the pictures at the unit section itself. The intent of this service is to support getting the deficiencies fixed rather than just put together a report. Deficiencies are placed on a punch list for distribution to staff or vendors. Our inspector holds an HVAC and sheet metal license in NJ.